Industrial Immersive 2025: Houston, TX, March 3-4, Westin Memorial City

Join ForgeFX at the 7th Annual Industrial Immersive Event in Houston, TX!

We’re thrilled to announce that ForgeFX’s CEO and Co-Founder, Greg Meyers, will be taking the stage at the 7th Annual Industrial Immersive Event in Houston, TX!

Session Details:

📌 Title: "Decoding XR Success: A Decade of Lessons With Fortune 500 Innovators"

📍 Location: Westin Memorial City, Houston, TX

📅 Date: March 3, 2025

🔗 Learn more and register: Event Link

Why You Can’t Miss This Session

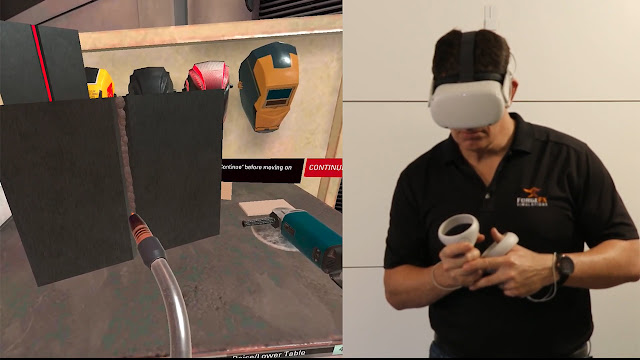

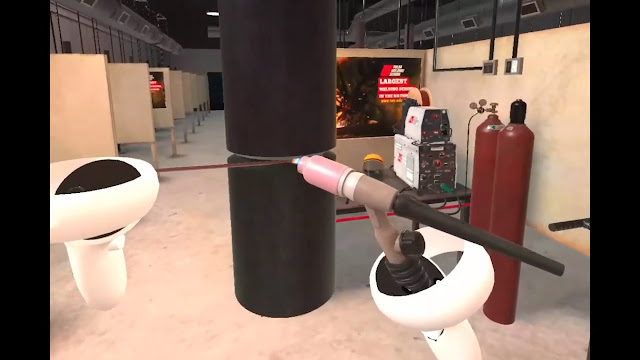

Greg Meyers has spent over a decade leading the charge in AR, VR, XR, and simulation-based training solutions for some of the world’s largest industrial enterprises. His expertise in delivering scalable, impactful immersive technology solutions has made ForgeFX a trusted partner for industry-leading Fortune 500 companies.

In this must-attend session, Greg will take a deep dive into:

✅ Key lessons learned from a decade of deploying XR solutions in high-stakes industries.

✅ What makes immersive technology succeed (and fail) at an enterprise scale.

✅ Real-world case studies showcasing the power of simulation-based training.

Whether you’re just beginning your XR journey or looking to refine your enterprise-scale immersive solutions, this session will provide actionable insights you won’t find anywhere else.

The Future of Industrial Immersive Technology

The Industrial Immersive Event has established itself as the premier gathering for XR, AI, and simulation professionals focused on revolutionizing training, operations, and workforce development. As industries continue to adopt immersive technologies, staying ahead of the curve is crucial. This conference brings together thought leaders, technologists, and innovators from energy, manufacturing, aerospace, healthcare, and beyond.

By attending Greg’s session, you’ll gain a front-row seat to the latest advancements, challenges, and breakthroughs in extended reality and simulation-based training. ForgeFX’s expertise in immersive simulations has helped companies enhance workforce training, reduce operational risks, and improve overall efficiency—don’t miss this chance to learn how your organization can do the same.

Join the Conversation

The event runs from March 3-4, 2025, offering a packed agenda of insightful keynotes, hands-on demonstrations, and networking opportunities. Be sure to mark your calendar and attend Greg Meyers’ session to gain exclusive insights into the future of industrial XR solutions.

We look forward to seeing you in Houston this March!